How are tumbled stones made ?

How are tumbled stones made ?

What are tumbled stones ?

Tumbled stones are small pieces of polished rock or mineral without definite shape, first intended for collection or decoration, they are now very popular because it is widely used for lithotherapy, reiki, or well-being in general (massage, etc ...). Present everywhere, almost all the mineral matter found on Earth is polishable, from the simple pebble picked up on the beach to the most precious crystal.

There are two special techniques for polishing a tumbled stone : tumbling barrel and by hand.

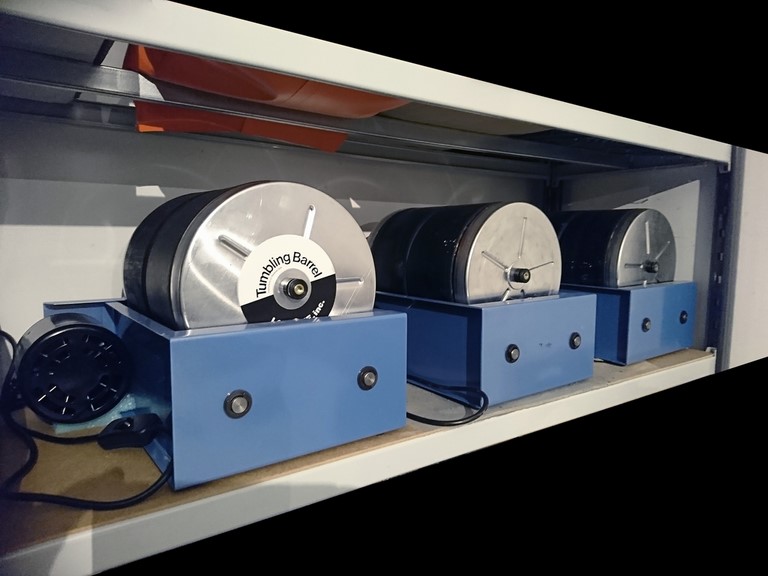

Tumbling barrel

It is a very simple machine that can be easily manufactured at home. It is a hermetic "cylindrical box" (the barrel) in which are placed the raw stones as well as abrasive and water. The rotation of the barrel is driven by a small motor. The stones and abrasive grains will shock and rub against each other for ten days, which will gradually round the stones. In fact, we reproduce in an accelerated way what happens in a stream from where the name of "tumbled stones". Small machines consist of a cylindrical barrel while semi-industrial or industrial models such as ours have hexagonal or octagonal walls to facilitate polishing. Once the stones are rounded, they must be polished to maintain a shiny appearance, as if they were wet. The process is repeated 5 times with an abrasive finer each time. After about 5 to 6 weeks we get a series of beautiful tumbled stones.

If we use electric machines today to polish stones, this has not always been the case. For a long time it was water mills that have driven the barrels and still today in some parts of the world it is still the case, especially in Peru where droughts related to global warming can ravage these fragile and local economies...

Advantages :

- Allows polishing in large quantities and evenly.

- Low cost technique. The tumbled stones polished with it rarely exceed 3€/pc on sale (variable prices depending on the rarity of the material).

- Autonomous polishing requiring only weak control.

Disadvantages :

- Machine quite expensive to buy. (150€ minimum)

- Noisy, even with rubber barrels.

- Only polishes hard and non-brittle materials with a hardness of 5 or more (very suitable for agate, chalcedony, jasper or quartz).

- Polishing of one type of stone per barrel to obtain a conclusive result.

Hand polishing

The cabbing machine

There are inexpensive tree with only one interchangeable grinding wheel. If the polishing work is daily, the purchase of a 6-wheeled cabbing machine quickly becomes a necessity (photo on the right). It allows to cut and polish a stone continuously without having to stop the machine and dismount at each wheel change. With the habit, a tumbled stone or a cabochon can be carved and polished in less than 15 minutes... Everything will depend on the hardness of the material and also its size and the desired end result, the bigger the stone, the longer it will take, a mirror polishing also takes many time...

A professional cabbing machine consists of a tree and 6 diamond grinding wheels of different grains (there are also cheaper silicon carbide grinding wheels but they are very tedious to use for all the stones of hardness superior to 5.5). The wheels are classified from left to right from the largest grain of abrasive to the finest. In order to obtain a beautiful polish, it is necessary to pass successively the totality of the surface of the stone on all the grinding wheels. An oversight and it is scratches that appear during the last polishing phases. The cutting is also done with water to cool the stone but also to recover all sanding particles that are harmful for the lungs. Once finished, we obtain a stone with a luster far superior to those polished by the barrel.

Advantages :

- Technique offering a high quality polish and controlled shaping, it is possible to eliminate parts of a stone that are not beautiful or cracked for example.

- Allows the polishing of fragile or hard materials (from 2 to 9 hardness).

Disadvantages :

- The price of the machine (more than 2000 €)

- Low productivity

- Ask for special attention and know-how to achieve a result

- High price of tumbled stones made with this method

Which stone for which polishing technique ?

On the other hand some tumbled stones are still polished by hand, they are naturally more expensive (usually more than 5€ each). This is the case of many Peruvian stones such as angelites, quality rhodochrosites, or chalcopyrites. Many Indonesian stones are also polished by hand, bumblebee jasper and blue amber especially.